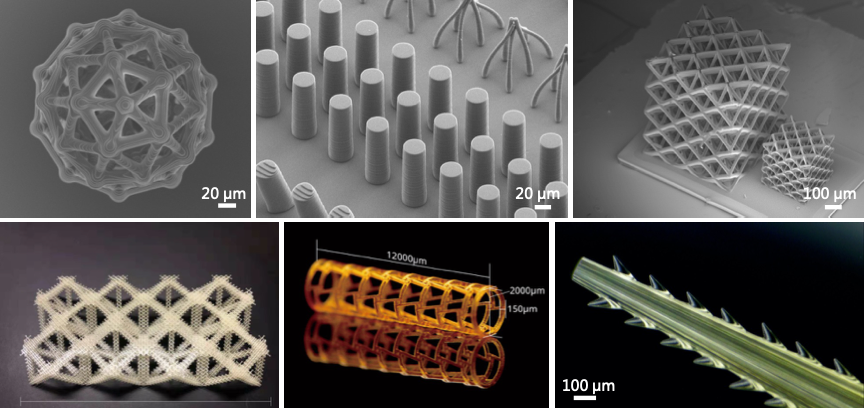

PμSL (projection Micro Stereolithography) is one kind of projection lithography used for three-dimensional (3D) printing (namely additive manufacturing). PμsL is extensive used in many fields of applications attributed to the advantages of high resolution, high precision, and high processing efficiency, low cost, capable for multiple materials and available for multi-scale manufacturing. In this paper, there will be some introductions from these following parts: Technological mechanism, Minimum printing feature size, Maximum printing area, Printing materials and the comparisons with some other 3D printing technologies and some industrial innovations.

Technological mechanism

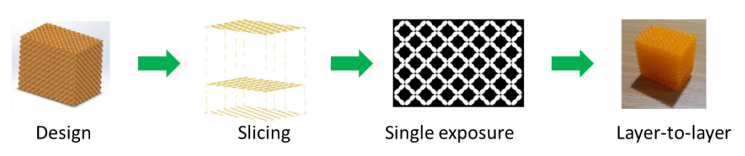

The whole procedures of PμSL-based 3D printing are shown in Figure 2. First, as the same as other 3D printing technologies, the model was built using CAD software. Then, the model will be sliced into a sequence of two-dimension (2D) mask images (digital mask) with given layer thickness. Following exposed by PμSL-based 3D printing system and each image is corresponded to one layer pattern. The exposure process for each layer proceeds iteratively until the entire structure is fabricated.

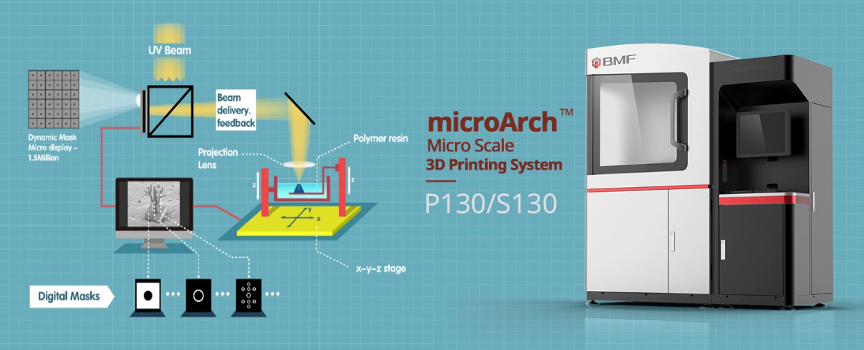

It’s pivotal for PμSL-based 3D printing is the photopolymerization of the curable resin under the exposure of UV light which makes the liquid into solid. The specific structures can be obtained relying on the digital dynamic mask formed by DMD (Digital Micromirror device) in the printing system. As can be seen from Figure 3, the slicing model data are delivered into the printing system (namely the data of 2D patterns delivered to DMD). The light projected on the DMD chip is shaped according to the predefined mask pattern. As a result, the specific structure can be prepared after the exposure by the projected UV light on the resins. In addition, a large scale structure can be also obtained by stitching in the way of moving the printing platform.

Figure 3. Typical PμSL-based 3D printing system

Minimum printing feature size

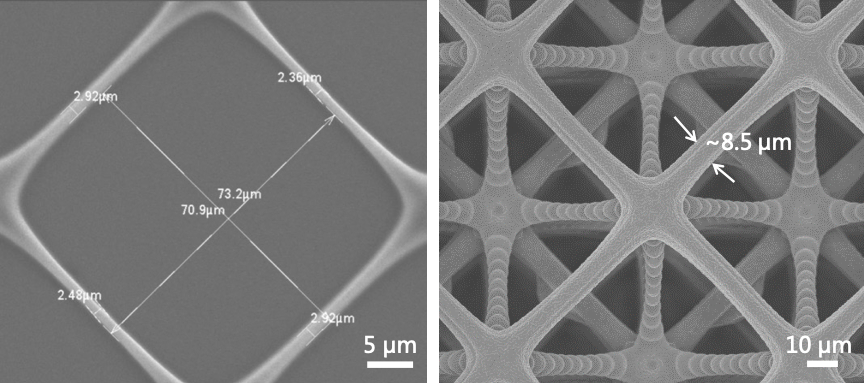

PμSL-based 3D printing is capable to get the resolution of several micronmeters or even hundreds of nanometers, in the favor of controlling the ratio of projection lens. BMF Material ( Shenzhen,Guangdong Province) has devoted into this technology for several years and launched a series of PμSL-based 3D printing system. Among them, the best commercialized one can achieve 2 μm of optical resolution (optical resolution here means each pixel size of the projected light). 2D grids with a linewidth of 2 μm and 3D microlattice with diameter of 8.5μm can be achieved by the systems from BMF Material, shown in Figure 4.

Figure 4 .2D grids and 3D rod arrays prepared by BMF Material printing system

Maximum printing area

PμSL technology is based the single exposure for entire surface while the exposed pattern is controlled by DMD. Usually, the maximum printing area depends on the number of DMD pixel and the optical resolution. The number of the DMD is defined by the chip, which means the maximum area of one single exposure is constant. Since the maximum printing area is contradictory to the optical resolution, as the optical resolution increased, the maximum printing scale decreased. Creatively, we explore the stitching mode to get the precise, large-area, multisclale structures achieved. For instance, the optical resolution and the maximum printing scale corresponded to both fixed projection and stitching are listed in Table 1 by BMF Material printing system.

|

Optical resolution |

Maximum printing area under single exposure |

Maximum printing area by stitching |

|

2 μm |

3.84 mm × 2.16 mm |

50 mm × 50mm |

|

10 μm |

19.2 mm × 10.8mm |

94 mm × 52mm |

Table 1. Comparison of optical resolution and maximum printing area under single exposure and stitching mode.

Printing materials

As was known that, PμSL-based 3D printing is based on the photopolymerization of the materials used for printing, normally, the materials are the photo-sensitive resins. Regards of the applications, there are various resins commercialized, such as rigid resin, tough resin, high-temperature resistance resin, biocompatible resin, flexible resin, transparent resin, hydrogel, etc. Moreover, composite resins with addition of functional particles can also be printed as well, such as magnetic particles added composite resins, ceramic-resin, metal-resin, etc.

Comparison with other 3D printing technologies

Shown in Table 2 is the comparison with other 3D printing technologies (already commercialized). Nowadays, fused deposition modeling (FDM) and PolyJet are two mainly used 3D printing technologies, which can produce large structure in the loss of high-precision. Scanning stereolithography(SLA) and two-photon polymerization based direct laser writing (TPP-DLW) have the distinguished advantage of high-resolution, however, the processing time cannot be ignored. Usually, the size of the structure by TPP-DLW is in the millimeter scale. Comparatively speaking, PμSL 3D printing can print large scale structure in a fast speed with high precision simultaneously.

|

Technology |

Highest XY resolution |

Maximum printing area |

Molding speed |

Feature |

|

PμSL |

2μm |

cm |

Fast |

High precision, fast in speed |

|

SLA |

~10μm |

cm |

Slow |

Medium precision, slow |

|

TPP-DLW |

< 50 nm |

≤mm |

Extremely slow |

Ultra-high precision, small overall size, slow in speed |

|

FDM |

~200μm |

cm |

Slow |

Rough surface, low precision |

|

PolyJet |

600 DPI (42.3 μm) |

≥cm |

Fast |

Low precision, fast speed, large size |

Table 2. Comparison of PμSL and other3D Printing technologies

Industrial innovations

Compared to the scholar researches, the demands to PμSL in the industry is much harsher, concluded the multiple materials for printing, larger printing scale, stable control of tolerance, etc. Given to these requirements, BMF Material has explored some innovations such as increasing Bubble scrapper assembly, Laser Displacement Sensor, Heating printing system, etc. With the purpose to fulfill the demand of industrial manufacturing, all these innovations are expected to improve the printing quality and tolerance controlling and capable to use more materials.

This paper is briefly focusing to present PμSL, which is a kind of high-precision, fast, large-scale 3D printing technology. PμSL is suitable for one-step molding of complex 3D structure with high precision, fast proving for molding to test and manufacturing functional devices in small batches, which is available for many applications. The examples of these applications will be on the way to be shown in the following series of columns.